Cereal AGROs

The Argo company has been working in the Sumy region for more than 20 years. It is engaged in the production of buckwheat and oatmeal from its own raw materials with subsequent wholesale sales. Made by Argo porridge is eaten not only in the region, but also, for example, in Israel. Company founder Sergei Pavlik told how the company has managed to stay afloat for almost a quarter century.

The founder of Argo, Sergey Pavlik, is from Donetsk, and there he began to build his own business. It was a trading company: different categories of goods, wholesale and retail. Over time, expanded to its network of stores, established sales outside the region ...

How often you can hear in these stories of formation, doing business, entrepreneurs have identified an unfilled niche, saw good demand and thought about their own production. The founders of the company decided on its direction: buckwheat and oatmeal. We started looking for a suitable location where there would be raw materials, production and specialists. Lucky. All parameters converged in the village of Rudnevo, Sumy region. The basis for the new production was the power of the collapsed Soviet economy.

“For the first 2-3 years, we worked without going to bed,” recalls Sergey Pavlik. - In three shifts, year-round. The area is focused on growing buckwheat, the processing plant was loaded at full capacity, 50 tons / day. Initially, we worked on purchased grain. The finished product sales system was built on the basis of those contacts that remained from the trading business. Delivered both wholesale and retail, in stores. At a certain stage (even before the events of 2013-2014) they abandoned their trading business: the situation has changed. The spontaneous trading of 1995 and the structured sales and distribution market of 2005 are radically different systems. Concentration on one type of business yielded results: it began to develop more actively. ”

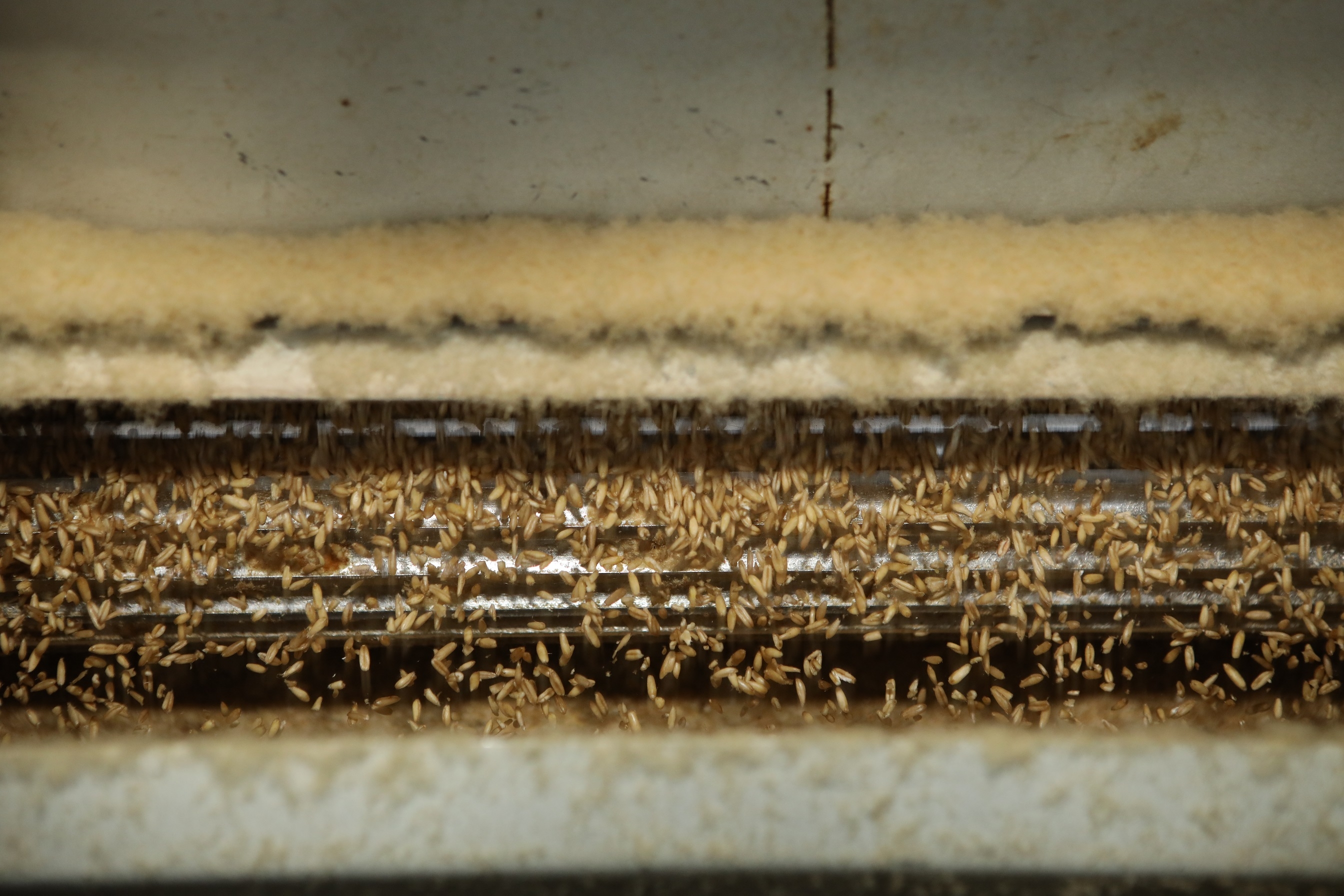

The first line of production was buckwheat. Purification of this culture, steaming, other processes from the state “from the field” to the state “to the counter” is a multi-stage and technological chain. For about five years, the production was single-product, then they built and equipped a new plant - for the production of cereals "Hercules". A spacious four-story building with its own mini-elevators, accommodating grain volumes for three days of work. Entering the workshop, oats go through up to 10 processing stages, including peeling. Several levels of cleaning, culling of impurities and substandard grains, steaming, crushing, drying ... The output of finished products from the "incoming" raw materials is about 65%. All production is as automated as possible, direct human labor - only at the stage of packaging in bags. Well and, of course, management and maintenance of lines. According to the plans of the entrepreneur, the "buckwheat line", while working in the old room, is gradually transferred to this workshop.

Both types of products are packed in bags of 25 and 50 kg, only wholesale sales. The company does not deal with light weight packaging and retail packaging. As Sergey Pavlik explains, this is a completely different business, other marketing schemes, and marketing. Now both directions work simultaneously or in turn, depending on the availability of orders. They did not expand the assortment, although such ideas did exist. But having studied the market, we came to the conclusion that other types of cereals will be less cost-effective and problematic. As it turned out, in Ukraine even an underground workshop can produce pearl barley, a crate, peas or millet, since there are no standards for them, DSTU. Buckwheat and oatmeal are more standardized, production is constantly monitored by the relevant public services. Argo has its own accredited quality laboratory. She checks the parameters of the incoming grain and the finished product.

According to Sergey Pavlik, the competition for cereals and buckwheat is palpable, but this is not a decisive factor. About ten fairly large processing enterprises cover the needs of all regions of the country. It is possible to enter the territory of the “coverage” of the Skvirsky bread products factory with its brand Skviryanka, giving a tangible price advantage for the end user. But it is unprofitable. Therefore, sales are concentrated in the region. 70% of consumers of Argo products are in the Sumy region, 25% are Chernihiv, Kharkov, 5% are exported. Products are sold in bulk, then they are packaged in branded packaging, sold by weight. For example, in the Sumy region, buckwheat and oat flakes produced at the Argo factory are sold under the Veselka brand. It is also delivered to Poland, Germany, Israel, which speaks of quality, because these countries have high requirements.

The products themselves sell well, you do not need to advertise them separately. Moreover, over 22 years of work in the market, the company has established distribution channels and good relations with partners. Direct sales, maintaining the SRM base, meeting delivery deadlines and guaranteed quality, good payment terms are fairly simple but working principles of “sustainability” in the market.

The main problem of Argo, like other manufacturers of these products, is not high competition, but the sharp decline in the country's population that occurred in 2014. “A large number of people left from different regions, and this continues further. In addition, we observe a decrease in consumption, a transition to other crops, a change in eating habits. Buckwheat cultivation has become unprofitable, the majority of farmers have long replaced it with sunflower, soybeans, wheat ... The market is unstable. Overproduction - a drop in value, difficulty in marketing. Underproduction and deficit by the state are blocked by import, and again the fall in prices. The main negative influence is exerted by products imported from Kazakhstan, Belarus and even Russia. It is often of poor quality, but cheap. And this hits our manufacturer, because customers choose the product with a wallet, ”says Sergey Pavlik.

Another factor influencing the market is the panic of the population. “There is a rise in price, you need to urgently purchase” - this motive of grandmothers provokes wholesalers to a similar stir, manufacturers with unrealistic efforts cover the demand. Then the wave subsides, and the grandmothers and wholesalers take out stocks from the bins for six months. And manufacturers have sales problems, downtime, cash gaps. It is impossible to make products in a warehouse in order to preserve the workload of personnel in this business due to the limited shelf life and the risk of damage by rodents.

Staff, workers - another topic for conversation. A hundred people work in the company during the season, and the rest eighty. The entrepreneur tries to find work for most workers all year round to keep them. Despite this, staff turnover is high, as Rudnevo is located almost on the border with Russia and close to Belarus. Many villagers, especially young ones, are inclined to travel to work in these countries and in Poland. Especially, having passed training and qualification at the enterprise. Fighting such a trend is difficult, but possible. Decent wages, good living conditions (there is a dining room, clean and comfortable facilities for recreation), significant investments in the social infrastructure of the village. The company constantly helps the local school, the house of culture, takes care of beautification, built a church. In a word, an active participant in the life of Rudnevo.

No matter how complicated the business, the owner of Argo sees the point in continuing and developing the company, adapting to new conditions. To reduce the cost of production and provide the plant with raw materials, the enterprise was engaged in agricultural production ten years ago. Today, Argo grows buckwheat and oats, as well as wheat and barley, which is calculated with the villagers for shares. Almost 1,600 hectares of unit land are in use by the economy. There is a full fleet of equipment for the full cycle of work. Its maintenance and repair (there are workshops) and even providing fuel and lubricants - a gas station.

Closed processes within the company help optimize costs, which means maintaining the profitability of the core business. A very important role in this is played by energy saving in the production process of the plant. The company has built its own gas boiler house, which produces steam for the production process and heating of utility rooms. Over time, it was converted for the disposal of buckwheat husk, because for a long time it was a headache for an entrepreneur. There were a lot of husks, and it had to be disposed of somehow. After some time, gas rose sharply, and this decision was timely and saving. The cost of heat and steam received from the husk is several times lower than when burning gas. On an old scheme, an enterprise would become unprofitable. Other waste is equally rationally used. Argo can be called resource-efficient production. All processes are configured for maximum efficiency and minimum waste. Such approaches help a lot to keep the company afloat.

The prospect of the company, which its head is currently working on, is access to foreign markets. Already not through wholesalers and by chance, but planned. Interested in European countries, markets in Georgia, Turkey, the Middle East. To begin with, Sergey Pavlik intends to analyze the situation there and look for customers directly by himself, bypassing intermediaries. The main competitor in foreign markets is Russia, its products are cheaper because it has tax benefits. So, you need to find ways to stay in price and “take” quality.

The Argo company can be attributed to business centenarians by Ukrainian standards. What contributed to this? Sergey Pavlik derives the formula: “We need patience and work. Do not chase fast success. Define your line and not bring chaos, spraying forces and means in different directions. If you hit the wall in one place, you will eventually achieve the result. If the same number of strokes falls on different points of the wall - maximum, in different places, plaster will sprinkle. Sustainability of a business is a fundamental investment in fixed assets and people. Modernization, flexibility and response to market challenges. Develop yourself, and develop the environment in which you work. Settlement, market, collective. It is necessary to value people and their reputation. And you need a little success. ”

Financial partnership

We have been serving at Raiffeisen Bank Aval for twenty years. During this time, they managed to take advantage of probably all types of products. Settlement accounts in hryvnia and currency, a salary project, credit cards are constant business companions. Overdraft is a solution that is simply indispensable during periods of production downtime, cash gaps or some operational business needs. The construction of a new workshop and its equipment could not have taken place without lengthy lending programs. These are constant needs. A line of credit helps in the acquisition of raw materials when its processed. Now a new expensive agricultural technology has gone, without which it is indispensable. For example, last year they bought a New Holland 400 tractor. Again we will buy equipment, part of the domestic one, under the compensation program. Raiffeisen Bank Aval is really a partner for us, and not just a structure that operates with our money.